Utilities

Increase hosting capacity.

Power Efficiency Issues

- 20 – 40% of incoming facility power is wasted due to power inefficiencies

- Inefficient power causes higher utility bills

- Critical shortage and availability of additional power on the power grid causes brown outs and black outs

- Inefficient power causes excess heat and fuel consumption in transformers and power distribution equipment

- Excess heat and fuel consumption causes greater emissions and increased carbon footprint

- Higher costs of environmental regulations impact profitability

The OmniPower ™ Solution

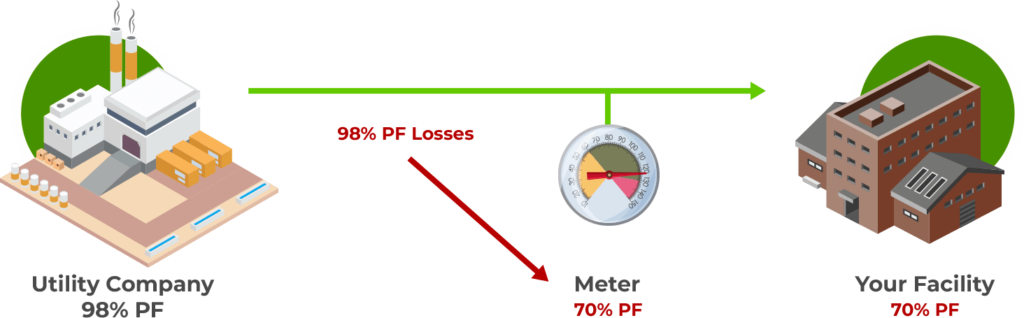

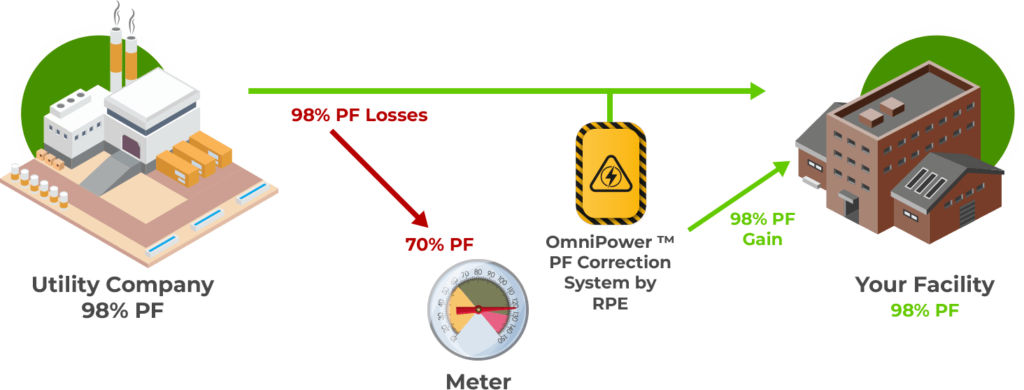

The OmniPower™ System is the only patented technology providing real-time, automatic control to lower total power at a customer’s premises. The System is a custom-built, enclosure-based power efficiency and conditioning system. The OmniPower™ Power Factor Correction System integrates a state-of-the-art Automatic Power Factor Controller (APFC), software, and a process to automatically maintain a continuous Power Factor (PF) correction to 0.98 PF. It includes banks of capacitors, automatic switching control circuits (which keep the power factor at .98 24-7), passive and active harmonic filters, and scalable, dynamic load balancing modules. The overall system capacity is scalable in 25KW, 50KW, or 100KW increments from 75KW up to 100s of megawatt. Custom power systems with excessive inductive/capacitive mismatch, multiple phase and frequency distortion, or harmonics will reap the maximum benefits of this solution.

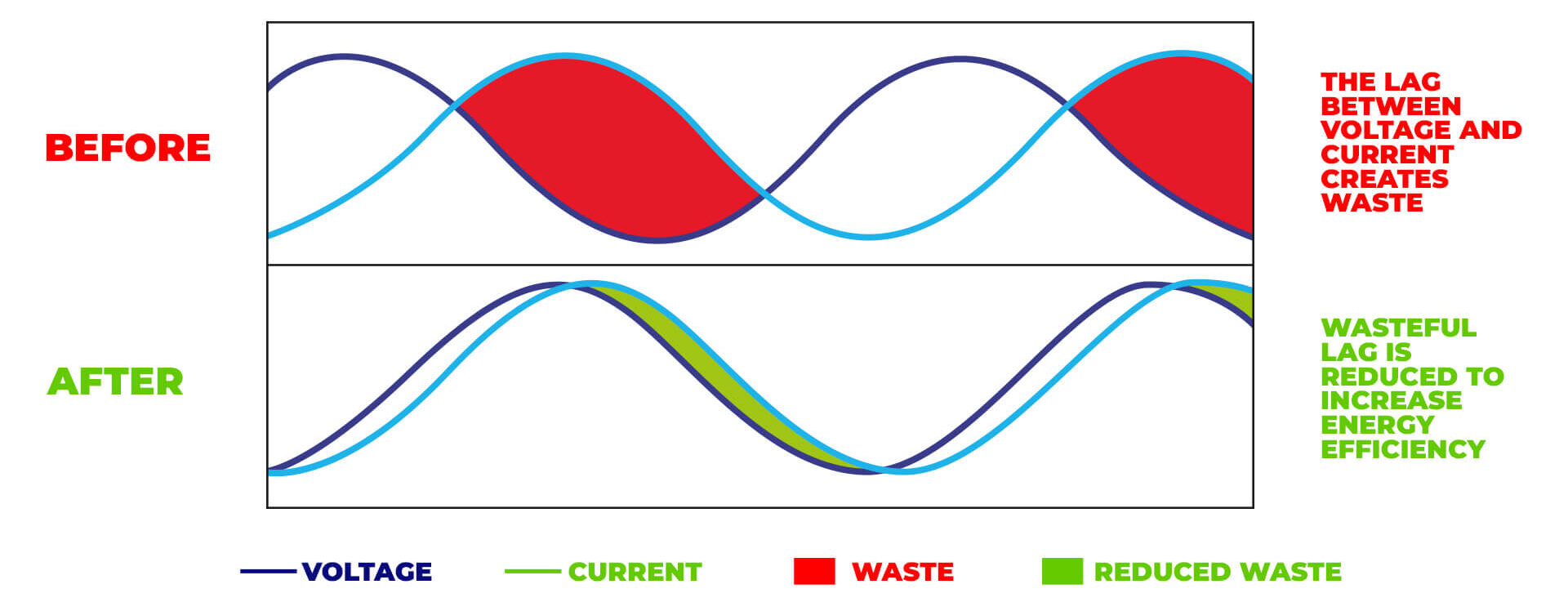

OmniPower ™ Patented Power Factor Correction Solution Decreases the delta between Current and Voltage automatically, 24/7, 365 days a year.

Advantages For Utility

RPE OmniPower™ Automatic Power Factor Correction System (APFC) is an integrated system consisting of multiple size steps and switched stages of capacitors, soft switches, active harmonic filters, passive harmonic filters, and load balancers.

- The RPE power conditioner will mitigate issues related to inrush power from GPU clusters and mechanical systems through several key features and functionalities:

a. Inrush Current Limiting: RPE power conditioners are designed to manage and limit inrush currents when power is applied. By employing soft-start mechanisms, the system gradually ramps up the power supply, reducing the initial surge that can cause stress on transformers and other electrical components.

b. Energy Storage: These conditioners often include energy storage components, such as capacitors or flywheels, which can absorb excess energy during peak demand periods. This stored energy can then be released smoothly to manage sudden increases in power demand, thereby reducing the impact on transformers.

c. Dynamic Load Balancing: The RPE power conditioner can dynamically balance the load across multiple phases. This balancing helps in evenly distributing the electrical load and preventing any one transformer or utility from being overloaded during GPU cluster operation.

d. Voltage Regulation: By maintaining consistent voltage levels during fluctuations caused by inrush currents, the RPE power conditioner can protect sensitive equipment from voltage spikes and drops, ensuring stable operation of GPU clusters and mechanical systems.

e. Harmonic Distortion: GPU clusters can introduce harmonics into the power system, which may lead to additional stress on transformers. RPE conditioners can filter out these harmonics, ensuring cleaner power delivery and reducing the risk of overheating and inefficiencies in transformers.

f. Real-Time Monitoring and Control: Advanced monitoring capabilities allow for real-time adjustments to the power delivery based on the current load conditions. This responsiveness helps in effectively managing the inrush currents and their effects.

Power factor correction equipment is an asset to Utility Companies. Our OmniPower ™ solution increases the capacity on distribution systems.

As motor load changes, the power factor is kept at a continuous optimum of 0.98 PF; we can observe the following effects:

- Line currents are significantly reduced

- kVAR is significantly reduced

- kVA is reduced

- kW is reduced

- kWH is reduced

- Conductor heating is reduced and equipment life extended

With Harmonic Filtering

- kW heating losses (I2R) from harmonic currents produced by VFDs, computers, LED lighting, solar power inverters, and other switching power supplies are kept to a minimum.

- “Dirty power” (mainly 5th harmonic currents) from inverters is filtered and not reflected/introduced into the power grid.

- “Clean power” results in reduced heating on pad mount transformers, pole-top transformers, and power transformers, leading to a longer life.

- Underground cable failure (approx. 30%) from harmonics heating effects can be reduced for fewer outages.

- “Clean power” from renewables enables the power grid to be more stable, predictable, and reliable, allowing protection settings to do their job.

Generation/Transmission/Distribution Losses

- NYSERDA report identified that for every 4 MW of energy produced, there are losses of 3 MW, leaving only 1 MW to be supplied to a customer.

- By saving 1 MW at the customer load, the utility can see upstream savings of 3 MW.

- Less grid buildout is required for transmission lines, transformers, substations, and other needed infrastructure improvements to handle the load growth.

- With more reactive power (kVAR) freed up, we can increase the grid’s spinning reserve margin to ride through emergency conditions.

Utility Carrier Benefits:

- Relieves stress from the grid

- Relieves load from the utility network

- Improves sub-station maintenance

- Increases sub-station longevity

- Improves transformer maintenance

- Increases transformer longevity

- Can be implemented on the Primary side, 13.8 KV to 35 KV

- Can be implemented on the Secondary side, 208V to 600V

- Reduces carbon dioxide and nitrous oxide from power production emissions

- Improves utility’s carbon footprint for new state and federal Government requirements

- Enables environmental efficiency rebates

- Enables and enhances building LEEDs certification

Green Power

- Reduction of kWH/day consumption produces less Green House Gases from fossil fuels

- Tonnage of CO2 saved promotes a Green Economy and enables environmental Corporate Targets to be met

What Your Savings Will Be

Savings

Footprint

Bill Savings

Maintenance

Savings

Footprint

Bill Savings

Maintenance

Strategic Materials Case Study

Easy Three-Phase Process to acquire OmniPower ™ Solution

Phase-1 Qualification: To “estimate power savings,” RPE electrical engineers analyze the customer’s One-Line Diagram and the most recent twelve months of power bills to determine if the customer is a candidate to install OmniPower™.

Phase-2 Testing: To identify “power savings,” RPE will have a third-party Professional Engineer (PE) and Qualified Testing Company conduct a power quality survey with properly calibrated meters at the load to determine kW, kVAR, Harmonics, Disturbances, and other electrical problems. Test duration is two weeks and a report is stamped by a state-certified PE.

Phase-3 Installation: RPE orders OmniPower™ Automatic Power Controller manufactured to the customer’s load characteristics and specifications and arranges for installation without interrupting power. RPE will install OmniPower™ in parallel to the system.

Pricing

There are two ways to acquire the OmniPower™ Automatic Power Controller.

Purchase Agreement. Customer agrees to purchase RPE equipment and a monthly service contract. RPE orders and installs OmniPower™ and conducts 24/7 monitoring and maintenance. This service contract is required as protected intellectual property (IP). Estimated ROI is typically 18 months after installation; thereafter all utility savings accrue to the customer.